PureWaterSF

The PureWaterSF project is a research project that explores how we can treat and reliably produce purified water on a small (building) scale using wastewater generated onsite.

For this project, the SFPUC will be taking approximately 80% of the recycled water currently produced by the constructed wetland treatment system called the Living Machine™ at the SFPUC headquarters. The PureWaterSF process will further purify this water, bringing it to a level that is expected to meet or exceed drinking water standards. Data from this process will be collected and analyzed, and the water produced will be returned to the building’s non-potable (non-drinking water) system for toilet flushing. This project is intended for research only, with the goal of collecting data that can inform a broader, statewide dialogue on purified water use. The project will also adhere to and help inform future California potable reuse regulations.

Did you Know?

- The Living Machine is one of the first buildings in the nation with onsite treatment of grey and black water to be recycled for toilet-flushing?

- The Living Machine reduces the SFPUC headquarters’ water use by about 65%, saving 800,000 gallons of water per year?

- Wetlands are often less expensive to build than traditional wastewater and stormwater treatment options, have low operating and maintenance expenses and can handle fluctuating water levels (USEPA, 2006).

- Advanced purification processes are already being used to recycle and reuse water on spaceships, and cruise ships? Even at Disneyland!

- In California alone, there are 9 other purified water projects underway including in Santa Clara, Los Angeles, Orange County, and San Diego?

- By 2027, the volume of recycled water produced in the United States is projected to increase 37% from 4.8 billion gallons per day to 6.6 billion gallons per day (WaterReuse, 2018)

-

Research Objectives

The goal of this research project is to demonstrate how advanced water purification and monitoring technologies can reliably convert building-sourced wastewaters into a high-quality supply to meet diverse end uses. Several objectives help us achieve this goal:

- Examine reliability of a water purification system at building-scale

The research examines the reliability of a purification system measuring common parameters such as chlorine, pH, turbidity (how clear the water is), and temperature. This information is regularly collected using real-time monitoring and provides valuable information about the reliability of these systems at a building level. - Create a research baseline through advanced water quality analytics

The project follows recommendations from state experts to use specific water quality analytics to address knowledge gaps in the industry. These analytics include nontarget analyses (NTA), which measure substances we have not typically measured or created targets for before, and biological assessments, which can test the overall level of bioactivity in water samples. Data from this research can help inform statewide regulatory deliberations. - Promote transparent science through outreach and communication

The project focuses on promoting transparent scientific practices through outreach and communication by using: factsheets, a digital wall display, a digital tour video, in-person tours and this website. All of these components work toward fostering a greater understanding of purified water in our communities. Public feedback will further inform future work by the SFPUC. - Provide new opportunities with on-site operator training

PureWaterSF provides a unique opportunity for operators to receive onsite training with a building-scale water purification system at the SFPUC headquarters. Operator feedback will help inform planning and system development.

- If you would like to learn more about purified water research in San Francisco, sign up for our email list.

- Take a short survey and let us know what you think about PureWaterSF.

- Register and tour the PureWaterSF Research Project at 525 Golden Gate Avenue in San Francisco.

- Examine reliability of a water purification system at building-scale

-

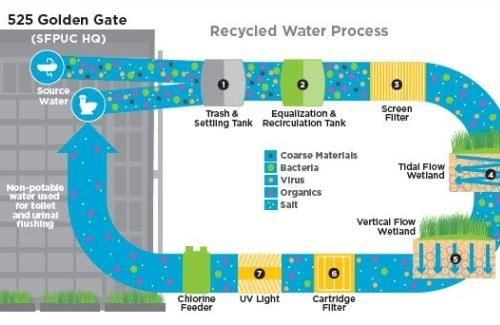

Living Machine System Schematic

The Living Machine™ is a constructed wetland system providing on-site non-potable water reuse at the SFPUC Headquarters (SFPUC HQ). It collects and treats the building’s wastewater and reuses this water for toilet flushing. The system has a capacity of 5,000 gallons per day.

- Primary Tank: wastewater is first sent to a primary treatment tank where sewage is settled and screened using a trash and a settling chamber to separate larger solids. The filtered wastewater then flows to the Equalization and Recirculation Tanks.

- Equalization and Recirculation Tanks: filtered wastewater is then sent to the Equalization Tank which holds back the wastewater and acts as a buffer until it can be sent to the Recirculation Tank. The Recirculation Tank doses the wetlands with a steady flow of wastewater throughout the day.

- Tidal Flow Wetlands: The Tidal Flow Wetlands are located outside the SFPUC headquarters along Golden Gate Avenue. These are designed to mimic natural tidal wetlands. Water from the Recirculation Tank fills the wetland planter boxes from the bottom up, and then water is drained by gravity back to the Recirculation Tank. Gravel media in these planters enables the growth of a healthy biofilm that is home to a diverse population of microorganisms which feed on nutrients in the wastewater. The planters are filled and drained 12 times a day.

- Polishing Vertical Flow Wetlands: at the end of the 12 cycles, the effluent is sent to the Vertical Flow Wetlands where remaining organic material and nitrogenous compounds are removed.

- Disinfection: The water is then sent through a disinfection process where it is filtered to remove solids and reduce turbidity, sent through an ultraviolet unit to deactivate bacteria and viruses, and sent through a chlorination tablet feeder to prevent growth in the building’s recycled water pipes.

- Recycled Water Tank: After the above treatment process is complete, the water is stored in the Recycled Water Tank and is used for toilet and urinal flushing.

Treated water held in the Recycled Water Tank is also now being used as source water for the PureWaterSF research project where the water undergoes advanced treatment up to potable standards and is analyzed for research purposes before being returned to the building’s non-potable system. Please see the Living Machine™ link for further information.

-

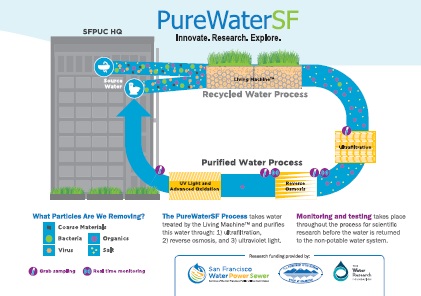

PureWaterSF System Schematic

The PureWaterSF system will add an advanced water treatment system onto the existing engineered wetland system of the SFPUC’s Living Machine™. The PureWaterSF system takes this already treated water and purifies this to generate (approximately) 1,296 gallons per day of highly purified water at a rate of about 0.9 gallons/minute. This high-quality water meets drinking water standards using the most advanced purification processes available including ultrafiltration, reverse osmosis, and ultraviolet light with advanced oxidation.

- Ultrafiltration:

After initial water quality sampling and testing, the water taken from the Living Machine™ first goes through ultrafiltration (UF) which involves passing recycled wastewater through very fine hollow fiber membranes and removing particulate matter, bacteria, and protozoa. After passing through the membrane, the filtered water mostly contains dissolved salt and organic molecules. Sampling: UF effluent is sampled for chloramines, free chlorine, nitrate, TOC, DOC, UV254, and turbidity. - Reverse Osmosis:

The next step is reverse osmosis (RO) where the water is pushed through a semi-permeable membrane at high pressure to remove impurities such as viruses, dissolved salts, pesticides, and most organic compounds. It is the same process used to desalinate seawater. Sampling: RO permeate is sampled for TOC, nitrate, nitrite, turbidity, pH, temperature, free chlorine, and UV254. - Ultraviolet Light with Advanced Oxidation:

The final step is ultraviolet light with advanced oxidation which exposes the water to ultraviolet (UV) light combined with sodium hypochlorite to disinfect any pathogens and to further reduce chemicals to non-detectable levels. Sampling: The finished water is sampled for free chlorine and UVT.

Downloadable Fact Sheets on the project are available here:

- Ultrafiltration:

-

PureWaterSF System Performance & Reliability

Ensuring Reliable System Performance:

Water testing is conducted at every step to ensure that each element of our system is efficiently and effectively removing the microorganisms it was designed to remove. This testing assesses the system’s performance in terms of the overall reliability of the system, and how well the system is able to continuously achieve water quality standards. Grab samples will be taken at regular intervals and analyzed for conventional water quality parameters, such as pH, chlorine, and hardness, as well as for potential contaminants, such as pharmaceuticals, bacteria or viruses.

At the end of the approximately 30-minute process, we are able to confirm that all the treatment goals are achieved, and we compare the purified water to drinking water standards.

Using Advanced Analytics to detect “unknown unknowns” in our water:

We then go one step further to gain a more holistic understanding of the water we are producing. We run a test that can indicate any trace of compounds such as pharmaceuticals and personal care products, which are ordinarily very difficult to detect. For this testing we use advanced data analytics, which includes bioassays (biological assessments) and non-target analysis (NTA) to measure biological effects of various trace level chemicals found in our water system. With this testing, we are trying to go beyond understanding what's been removed toward a better understanding of what remains in the water.

Real-Time Monitoring:

While the system runs, it conducts a continuous real-time monitoring to assess system performance and overall reliability. This real-time monitoring assesses the following standard measurements of water quality:

Total Dissolved Solids (TDS) - TDS are inorganic salts and organic matter that are dissolved in water. TDS is an indicator of general water quality. The EPA sets a secondary drinking water standard for TDS at 500 mg/L. An elevated level of TDS is not a health hazard.

Total Organic Carbon (TOC) - TOC is a measure of the level of organic molecules or contaminants in purified water. TOC in itself has no health effects but provides a medium for the formation of toxic disinfection by-products.

Turbidity - Turbidity is the measure of relative clarity of a liquid. Material that causes water to be turbid include clay, silt, finely divided inorganic and organic matter algae, soluble colored organic compounds, plankton, and other microscopic organisms.

Ultraviolet Absorption (UVA) - UVA represents the amount of light absorbed by constituents within water (light energy that does not reach the detector). UVA is commonly used as an indicator of general water-quality, or the potential for disinfection by-product formation.

-

Our Project Partners

The team assembled for this research project is uniquely qualified in its experience with regulatory development, design, permitting and implementation of purified water projects.

The SFPUC is a leader in the innovative and sustainable use of water in an urban setting. With adoption of the Non-Potable Water Ordinance in September 2012, the SFPUC installed a constructed wetland treatment system called the Living Machine™ in its headquarters. The SFPUC is conducting this research project to investigate how to further purify this treated water to drinking water standards with direct reuse.

The Water Research Foundation (WRF) is a leading not-for-profit cooperative advancing water science to protect public health and the environment. It is governed by utilities and delivers scientific research solutions and knowledge to stakeholders for drinking water, wastewater, stormwater, and water reuse. WRF is supporting the operation and outreach components of the PureWaterSF project.

The U.S. Bureau of Reclamation (USBR) manages, develops and protects water resources for the American public in an environmentally and economically sound manner. USBR supporting the building-scale treatment for direct potable water reuse and intelligent control for real time performance monitoring under their Desalination and Water Purification Research and Development Program (DWPR).

Carollo Engineers is an environmental consulting firm specializing in planning, design, and construction of facilities for water and wastewater. Carollo has been an industry leader in researching potable reuse treatment trains and monitoring systems and provides technical expertise in the design, installation, and monitoring of the PureWaterSF system.

Woodard & Curran is an integrated engineering, science, and operations company with services addressing infrastructure, environmental, water resources, energy, and manufacturing challenges. For the PureWaterSF project, the firm supports the SFPUC in project coordination, grant administration, and demonstration project installation as well as internal and public outreach.

Data Instincts specializes in public outreach and education for water and recycled water projects. The firm is supporting the SFPUC in the development of public outreach and educational materials for the PureWaterSF project. Data analytics for the PureWaterSF research project is supported by:

Southern Nevada Water Authority (SNWA) is a collection of seven local water and wastewater agencies formed to address water issues on a regional scale and to provide sustainable, adaptive, and responsible water service. SNWA will monitor Pharmaceuticals and personal care products (PPCPs), perfluorinated compounds (PFCs), NDMA, NDMA FP, THM/HAA FP, and fluorescence EEM, will on a monthly basis for this research project. This work will be done by Dr. Eric Dickenson at SNWA.

The University of California, Davis (UC Davis) will provide a non-target analysis (NTAs) and bioassays (biological assessments) to test for the presence of certain chemicals in the water. These advanced analytics will be conducted monthly by Dr. Michael Denison at UC Davis, a professor with the Department of Environmental Toxicology. All of the above analyses follow recommendations of the State Water Resources Control Board to use NTA and bioassays to better grasp the significance of “unknown unknowns” in our water system.